Loading... Please wait...

Loading... Please wait...- Home

- Hdpe Valves

- 4" Compact Flanged Hdpe Combination Foot Valve With Screen

- Home

- Other Products

- Hdpe Check Valves

- 4" Compact Flanged Hdpe Combination Foot Valve With Screen

- Home

- Black Hdpe Butt Fusion

- Hdpe Check Valves

- 4" Compact Flanged Hdpe Combination Foot Valve With Screen

- Home

- Hdpe Valves

- Hdpe Combination Foot Valves

- 4" Compact Flanged Hdpe Combination Foot Valve With Screen

Categories

4" Compact Flanged Hdpe Combination Foot Valve With Screen

Product Description

4" Compact Flanged Hdpe Combination Foot Valve With Screen

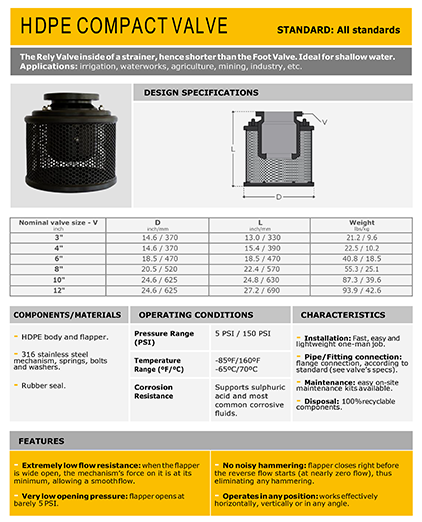

FLAPPER CLOSED BY SPRING ACTION

An outstanding feature of the TERMOPRO PolyCheck Valve is the unique method of applying spring action to the closure of the flapper. In the 6-8-10-12” valves the closing mechanism utilizes a knuckle action with two springs acting at the joint of the knuckle. When the flapper is closed, although the spring action is at a minimum, mechanical advantage of the knuckle joint multiplies the spring pressure many times, holding the flapper against the seat with much greater force than if the springs were acting directly on the flapper itself. In the 3” and 4” valves we have developed a new knuckle joint that has a single spring that improves performance.

COMPACT. The check valve goes inside the strainer, this way the foot valve is shorter allowing it to work in shallow water

STURDY CONSTRUCTION. Reliable one piece corrosion proof High Density Polyethylene body and all working parts in stainless steel. Valves are conservatively rated at 150 psi.

MINIMUM RESISTANCE TO THE FLOW. The inherent characteristics of a knuckle joint result in a minimum force being applied against the flapper when it is in the wide open position. When the flapper is open, even though springs are extended to their maximum, the actual force on the flapper is at minimum, assuring a minimum restriction to the flow

NO NOISY HAMMERING. Hammering is caused by the sudden stoppage of the reversal flow. To operate silently, without noisy hammering, a check valve must close quickly the moment the reversal flow starts, or when flow is zero. The spring tension on the flapper, actually closes an instant before the reverse flow commences, thus eliminating any hammering.

VERY LOW OPENING PRESSURE. Flapper requires less than 5psi to open.

OPERATES IN ANY POSITION. Regardless of the position in which it is installed – horizontal, vertical or angular - the TERMOPRO PolyCheck Valve operates normally and effectively.

EASY TO INSPECT AND MAINTAIN. The TERMOPRO PolyCheck Valve can be readily removed for inspection. All internal working parts are easily accessible and replaceable without the use of special tools. Simplicity of design assures long, trouble-free service.

The strainer has at least 8 times bigger filter area than the suction area making it ideal for dirty water.

Specifications Sheet

Certificate of Compliance TermoPro

Certificate of Origin TermoPro