Loading... Please wait...

Loading... Please wait...- Home

- FAQ

Categories

FAQ

FAQ

Frequently Asked Questions HDPE Pipe for Water Distribution and Transmission Applications

A. GENERAL

Q. 1 Is HDPE pipe safe for drinking water?

Yes. HDPE pipes certified for potable water applications are produced from pressure rated polyethylene compounds approved by NSF for public drinking water service.

Q. 2 Is HDPE pipe available in both ductile iron pipe size and iron pipe size outside diameters?

Yes, HDPE pipe is available both in iron pipe (IPS) and ductile iron pipe sizes DIPS), sometimes also known as cast-iron pipe sizes (CIPS). IPS sized HDPE pipe has the same outside diameter as black iron or carbon steel pipe. DIPS sized HDPE has the same outside diameter as cast/ductile iron pipe.Typically, ductile iron pipe sizes are available from 4- inch to 36-inch diameters. Iron pipe sizes are available from ¾- inch to 65-inch diameters.

Q. 3 Is small diameter HDPE pipe and tubing available in both iron pipe size inside diameter controlled and copper tube size?

Yes, small diameter HDPE pipe products are available in both inside diameter controlled (SIDR) and copper tube size outside diameter controlled (CTS-SDR). Typically, SIDR pipe is available from ½-inch to 3-inch diameter while copper tube size products are typically available in sizes ¾-inch to 2-inch.

Q. 4 Where can dimensional information such as outside diameter, wall thickness and inside diameter of the various sizes of HDPE pipe be found?

Normally, they will be found in the published literature of the HDPE pipe manufacturer and in ASTM standards. They can also be found in the Appendix to Chapter 6 of PPI’s Handbook of Polyethylene Pipe, 2nd ed.

Q. 5 What does the acronym HDPE stand for?

HDPE stands for High Density Polyethylene.

Q. 6 How does the use of HDPE pipe save money for a utility?

HDPE pipe provides the lowest life cycle cost when compared to other systems due to significantly reduced or no leakage, increased billable dollars, water conservation, fewer new water-treatment plants, reduced maintenance crews, reduced seasonal water-main breaks, and no loss in flow capacity over the long term. Refer to paper by CSIRO, Life Cycle Analysis of Water Networks, presented at Plastics Pipe XIV, Budapest, 2008.

Q. 7 Is HDPE pipe a green solution for piping?

Yes. It is safe when manufactured, used, or incinerated. It helps preserve water and electricity as there is no loss of water through the fused joint.

Q. 8 What do the terms DR and SDR mean?

DR stands for Dimension Ratio which is the average outside diameter (note: DR is also used for PVC pipe) divided by the minimum wall thickness. A StandardDimension Ratio (SDR) is a specific DR based on ANSI preferred number series. The use of SDR’s enables manufacturers to produce pipe to a set of standardized DR’s. SDR’s include 9, 11, 13.5, 17, 21,26, and 32.5. All SDR’s are DR’s, but not all DR’s are SDR’s.

Q. 9 Why is a fusion joint better than a gasket joint?

A fusion joined pipeline may be thought of as a continuous pipeline without joints. On the other hand, gasket joints are a potential source of leakage and lost water in many water systems. Leaks may occur if the gasket is improperly installed, if dirt or grit sticks to the gasket, if the gasket is not properly lubricated, if negative pressure (vacuum) occurs in the pipeline, if ground movement or sub-trench consolidation occurs, if significant thermal change occurs and if gaskets are blown out due to surge pressures. Fused joints are far superior to gasket joints for leak prevention.

Q. 10 Will trenchless installation save money over open cut trenching?

Everyday more utilities realize the advantages of trenchless technologies. More trenchless projects are being installed than in the past because of cost savings. Savings can result from quicker installations, faster permitting and design time, fewer disruptions to business and residents, less damage to parks and tress, and less disturbance to road beds (and subsequent road repair.)

B. Engineering Properties & System Design

Q. 11 Is thermal expansion and contraction of HDPE pipe a problem?

No. All pipes expand and contract with change in temperature. The key is management of the resultant thermal strain. As with all materials, expansion and contraction must be taken into consideration when designing a HDPE piping system. Buried pipelines usually do not move due to soil friction. However, thermal effects must be considered for above grade applications. The unrestrained coefficient of thermal expansion for HDPE pipe is approximately 9x10-5 in/in/oF. Information regarding thermal calculations for restrained and unrestrained above-ground and slip-lined pipelines can be found in PPI’s Handbook of Polyethylene Pipe, 2nd ed.

Q. 12 After HDPE has been buried and allowed to relax, will the pipe continue to expand and contract a great amount with temperature variations?

No. When HDPE pipe is buried, the temperature of the system becomes much more stable than an above ground pipeline and therefore will exhibit far less dimensional change. In most systems, buried HDPE pipe does not move after it is buried.

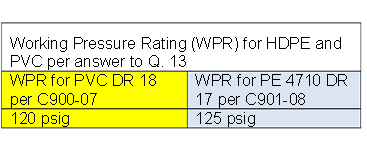

Q. 13 Why is there a difference in pressure rating (PR) and working pressure rating (WPR) when comparing HDPE pipe and PVC pipe?

The term pressure rating (PR) refers to the static pressure rating of the pipe, calculated from the hydrostatic design basis (HDB) with an appropriate design factor (DF) and is for a pipeline with no flow. However, all municipal water systems involve flowing water. For example, HDPE (PE4710) DR 17 pipe has a static pressure rating for water of 125 psig. The working pressure rating (WPR) is based on actual system requirements and is a dynamic pressure rating, that is, a pressure rating for pipe with flowing water. The WPR includes an allowance for water hammer surge pressures. At a daily recurring average flow surge velocity of 5 fps and at 80oF, the working pressure rating of HDPE (PE4710) DR 17 pipe is also125 psig; similarly, the working pressure rating for PVC DR

18 is 120 psig per AWWA C900-07, Equation 4. As such, PE 4710 has a higher working pressure rating than PVC at these common conditions. A summary is shown below:

Also, based on AWWA C900-07, Example B.2 modified with 5 fps recurring surge velocity, the estimated number of cycles to failure for the DR18 PVC pipe is less than 1 million cycles and the Fatigue Life is about 20 years which is less than half of the 50 year Design Life that was required in the example; in addition, the assumed 55 cycles per day may not be adequate; assuming 1 surge cycle every 15 minutes (96 cycles per day) and the 5 fps recurring surge velocity results in a Fatigue Life of about 11 years. On the other hand, IGN 4-37-02, “Design Against Surge and Fatigue Conditions for Thermoplastic Pipes”, can be used to show that under the same conditions, an HDPE DR17 pipe has a fatigue life of 10,000,000 cycles or in excess of 100 years. This striking difference is due to HDPE’s toughness and fatigue resistance.

Q. 14 Where can I find engineering properties such as the modulus and tensile strength values for HDPE pipes?

Engineering data for HDPE pipes may be found in Chapter 3 of the PPI’s Handbook* of Polyethylene Pipe, 2nd ed.

Q. 15 Do I have to be concerned with the long-term effects of creep?

All plastic materials, including HDPE and PVC, are subject to creep. Proper design, such as using the long-term modulus of the material where appropriate, accounts for creep effects.

Q. 16 Is there a flow loss in HDPE pipe due to the inner bead resulting from the butt fusion process?

The fusion bead has very little effect on the flow as it is basically rounded and protrudes very

little on the inside surface of the pipe Secondly, the Hazen-Williams C-factor of 150 takes into account the inner bead. Field tests confirm that a 150 C- factor used in the Hazen- Williams equation properly calculates actual flow and that the bead is of no hydraulic significance for either pressure or flow. The Hazen-Williams Friction Factor, C, for PE pipe was determined in a hydraulics laboratory using heat fusion joined lengths of pipe with the inner bead present.

Q. 17 Will sunlight adversely affect HDPE pipe?

Sunlight is not a concern if black pipe is used. Carbon black, utilized in most all HDPE pipe is the most effective ultraviolet stabilizer and therefore, black is the recommended pipe color for exposed long term service or storage. Pipe of this color will provide decades of outdoor use similar to that of black power-line cable jacketing. HDPE pipe produced in nonblack colors may also be supplied for outdoor exposure (storage and use) but its life expectancy is much less and is usually specified for a particular time period. Questions on this topic should be referred to the pipe manufacturer.

Q. 18 What is the life expectancy of HDPE pipe in water applications?

Many installations of HDPE pipe in water applications are already reaching 50 years of successful service. The polyethylene pipe industry estimates a service life for HDPE pipe to conservatively be 50-100 years. This relates to savings in replacement costs for generations to come.

Q. 19 Will HDPE pipe float in water?

Yes, HDPE pipe, due to its density being slightly less than water, will float even when full of water. When it is desired to ensure flotation of the line, various forms of collars, saddles, and strap-on flotation devices are available. For underwater anchored pipeline installations, it is important to specify the proper weights and spacing of the weights. Screw-anchors are a practical alternative. Whenever possible, an underwater pipeline should be installed in a trench with protective crushed rock cover. Refer to Chapter 10 of the PPI Handbook of Polyethylene Pipe, 2nd ed.

Q. 20 What is the max-min temperature range across which HDPE pipe for water pressure applications may be used?

HDPE pipe’s typical operating temperature range is from -40oF (-400C) to 140oF (60oC) although some products may be pressure rated for service as high as 180oF (82oC). Since water freezes below 32oF (00C) the practical lower temperature limit for water is 32oF (0oC). Consult with the pipe producer for information on applications.

Q. 21 When using HDPE pipe, will the pipe deliver the same flow-rate as the modestly larger ID ductile-iron pipe with the same outside diameter?

The inside surface of HDPE pipe is devoid of any roughness which places it in the “smooth pipe” category, a category that results in the lowest resistance to fluid flow. For water applications, HDPE pipe’s Hazen and Williams C factor for design is 150 and does not change over time. In contrast, the C factor for iron pipe and other traditional piping products declines dramatically over time due to corrosion and tuberculation or biological build-–up. In view of these advantages, it is often possible to utilize HDPE pipe of smaller inside diameter than Ductile Iron pipe, and still achieve or exceed the project’s required flow parameters. A detailed examination of the flow computations is encouraged. For flow factors and hydraulic design equations refer to Chapter 6 of PPI’s Handbook of Polyethylene Pipe, 2nd ed.

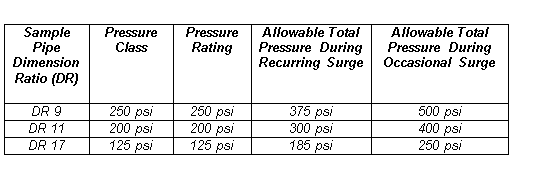

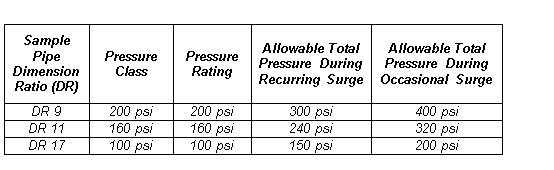

Q. 22 What is the maximum water pressure rating for HDPE pipe?

The maximum rating depends on several factors, the material designation code from which the pipe is made, the DR of the pipe, and the design operating temperature of the application. Refer to the tables below for sample ratings and allowable pressures:

The following table gives the Pressure Class per AWWA C901-08, the Pressure Rating and Allowable Total Pressure During Surge for PE4710 pipe at 80o F.

The following table gives the Pressure Class per AWWA C901-08 and AWWA C906-07, the

Pressure Rating and Allowable Total Pressure During for PE3608 pipe at 80oF.

Q. 23 What is the safe peak pressure (surge plus pumping) for HDPE pipe?

AWWA C901 defines two types of surge pressure, recurring and occasional. The safe peak pressure or allowed total pressure for HDPE pipe is 1.5 times the pipe’s pressure rating for recurring surge, and 2.0 times the pipe’s pressure rating for occasional surge. For instance a DR 11 PE 4710 has a pressure rating of 200 psig at 80oF and can safely handle total pressure during recurring surge of 300 psig and total pressure during an occasional surge of 400 psig. Refer to the answer under Q. 22 for additional data.

Q. 24 What is the maximum flow velocity for HDPE Pipe?

In a pumped system the maximum operating velocity is limited by the surge pressure capacity of the pipe. The Plastics Pipe Institute’s Handbook of Polyethylene Pipe states that “if surge is not a consideration, water flow velocities exceeding 25 feet per second may be acceptable.”

Q. 25 How does surge pressure in HDPE pipe compare with DI or PVC pipe?

Surge pressures in HDPE pipe are significantly lower than in DI pipe and lower than PVC pipe due to the lower value of dynamic modulus for HDPE. For example, a velocity change of 5 fps would cause a 51 psig surge in HDPE DR 17 pipe, a 87 psig surge in PVC DR 18 pipe, and a 262 psig surge in DI Class 350 lined pipe. Lower surge pressures often means longer life for pumps and valves in an HDPE pipeline, as well as lower pressure class pipes.

Q. 26 How does HDPE pipe’s capacity for recurring surge pressures (fatigue) compare to other pipes?

HDPE has exceptional capacity for handling recurring surge pressures. For example, in AWWA standards recurring surge pressure must be subtracted from PVC pipe’s Pressure Class whereas PE has resistance up to 150% of its Pressure Class. Marshall and Brogden report on the cyclical fatigue strength of PVC and HDPE and their report shows, at a cyclical stress range of 10 MPa (1450 psi) some PVC pipes failed at approximately 400,000 cycles whereas HDPE pipe reaches 10,000,000 million cycles before failure.

Q. 27 What are the safe maximum and minimum burial depths for HDPE pipe? Safe burial depths vary and should be calculated. In lieu of calculations, AWWA states that for an embedment soil with an E’of 1000 psi and no surface water, HDPE pipes with DR’s ranging from 7.3 to 21 can be safely buried from a depth of 2 ft to 25 ft where no traffic load is present and from 3 ft to 25 ft where H20 live load is present. However, most HDPE pipes can be buried to deeper depths, e.g. HDPE leachate collection pipe in landfills often have cover depths in excess of a hundred feet. Equations for calculating burial depth can be found in Chapter 6 of PPI‘s Handbook of Polyethylene Pipe, 2nd ed.

Q. 28 Is HDPE pipe suitable for use under railroads?

While HDPE pipe is structurally capable of direct burial under railroads it is not recommended under a railroad mainline unless it is encased for safety reasons. In fact, many if not most railroad specifications require that pressurized pipes located beneath rail lines must be encased, and this requirement applies regardless of pipe material. However, uncased direct burial may be considered for use under rail lines located within plant yards.

Q. 29 Are thrust blocks required with HDPE pipelines?

No. HDPE pipe and fittings joined by heat fusion are self-restrained in all applications, and therefore do not require thrust blocks, provided the entire system is fused. Thrust blocks may be required in cases where special gasketed mechanical fittings are used. This may be necessary to prevent separation of the gasketed joint just as it is required for gasketed PVC and ductile iron pipe in pressure applications. Detailed discussion of this topic can be found in Chapter 9 of PPI’s Handbook of Polyethylene Pipe, 2nd ed. Publications available from the pipe manufacturer may also cover this subject.

Q. 30 Can pipe-bursting technology be used on ductile-iron and cast-iron pipes? Yes, pipe bursting has proven to be a very valuable means of pipeline rehabilitation. The pipeline rehabilitation industry has adopted “pipe bursting” as the name of the process of rupturing brittle pipes (e.g., cast iron, clay, etc). A variation employed for ductile materials (i.e., ductile iron, steel, etc.), is called “pipe splitting”, which uses cutters to achieve enlargement of the host pipe. Preparation of the host pipe to receive the HDPE pipe is accomplished with a cone shaped head in both bursting and splitting processes. Refer to PPI Handbook of Polyethylene Pipe, 2nd ed., Chp 16.

Q. 31 How does the impact strength of HDPE compare with other pipes?

HDPE is a ductile material and has exceptional impact strength. HDPE’s superior impact strength provides a piping system that is near impervious to impact damage and to damage from improper tapping. In the real world, engineers understand that pipes must be tough and resist impact and handling damage. HDPE pipes are field tested and proven to be impact tough.

Q. 32 Will the presence of hydrocarbons in soils in which HDPE pipe is buried affect the pipe or permeate through its wall into the water stream?

AWWA has addressed concerns regarding hydrocarbon permeation by including a permeation statement in all of its pipe standards including standards for polyethylene (PE) (C901-08 p. 6, C906-07 p. 6), polyvinyl chloride (PVC) (C900-07 p. 6, C905-97 p. 3), steel (C200-05, p. 7), ductile Iron (C110-03, p. 3), and others. Hydrocarbons do not degrade polyethylene but can diffuse through the wall of HDPE pipe in areas of gross contamination. The exterior contact may affect saddle fusion connections, thus, after HDPE pipes have been exposed to grossly contaminated soils, mechanical connections may be preferred. In addition, while measures need to be taken to limit the impact of hydrocarbon permeation, the vast majority of HDPE water pipe installations will never be impacted by this problem. For more detailed discussion and information on this topic log on to: http://plasticpipe.org/pdf/ppi-comment-permeation-hydrocarbons.pdf

C. JOINING

Q. 33 How are HDPE pipe segments joined and connected?

HDPE pipe is easily and dependably joined using the standardized butt-fusion procedure. In this process matching ends of the pipes to be joined are aligned and heated with standard tools until the surfaces have become molten. When engaged under moderate pressure, the melt faces flow together forming a monolithic, homogeneous joint that, as the material cools, yields joints that are as strong as or stronger than the pipe itself.

There are several other well established heat fusion procedures used to join HDPE pipe such as electrofusion, which is exceptionally well suited for the assembly of pipe to fittings, or for making tie-ins or repairs, and saddle fusion which is used for the attachment of service fittings to HDPE mains. More details of some of these heat fusion procedures can be found in ASTM standards such as F2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings, AWWA Manual M55, “PE Pipe – Design and Installation, and in Chapter 9 of PPI’s Handbook of Polyethylene Pipe, 2nd ed. In addition, most of the pipe / fittings producers publish literature covering their recommendations for heat fusion joining of their products.

Apart from the heat fusion process of joining HDPE pipe, it can also be joined successfully with a variety of mechanical style fittings. Details of these joining systems can also be found in Chapter 9 of the Handbook mentioned above or by consulting directly with the pipe manufacturer.

Q. 34 How long does it take to make a butt fusion joint in HDPE pipe?

The time required to make a butt fusion joint is dependent upon the pipe wall thickness and diameter, and the field weather conditions. The thicker the pipe being joined the longer it takes to make a butt fusion joint, due to heating and cooling time requirements. An estimate on 6” DR11 pipe would be about 4 to 5 minutes to load the pipe, face it, heat it and apply the fusion force. An additional 5 to 6 minutes would be required to let the joint cool under pressure. A rough guide is to approximate 1-1/2 to 2 minutes per diameter-inch per joint. Alternatively, the use of certain other proven and validated industry fusion technologies may shorten the cooling time

Q. 35 Can HDPE pipe be fused and installed in sub-zero weather conditions?

Yes, but the operator and fusion machine must be protected from the, wind, moisture or blowing snow so that the heater plate uniformly heats the ends of the pipes. Please refer to the pipe manufacturer’s recommendations for fusing and installing HDPE pipe under these conditions or the cold weather guidance in ASTM F 2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings. For situations in which weather conditions prohibit fusion joining, mechanical connections should be considered.

Q. 36 What inspection criteria are used to assure quality heat-fusion joints?

First, insure the fusion joint is made in accordance with PPI and/or the pipe/fitting manufacturer’s fusion procedure guidelines. This could be accomplished by recording either manually or by an electronic data logging device the critical parameters of each fusion joint and by comparing this data to the approved standard to prevent an improperly fused joint from being buried in the ground. Second, the time proven method used for field inspection of fusion joints is visual examination of the melt bead. Many pipe manufacturers provide printed or video examples of melt beads illustrating quality and sub-standard heat-fusion joints. . Refer to ASTM F2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings.

Q. 37 Should the butt fusion bead be removed from an HDPE pipe joint?

Refer to Chapter 9 of the PPI PE Handbook.

Q. 38 Is extensive training required to operate a fusion machine?

Most people can be trained quickly to properly fuse HDPE pipe; for assistance, refer to PPI TN42, Recommended Minimum Training Guidelines for PE Pipe Butt Fusion Training Operators for Municipal and Industrial Projects.

Q. 39 How do heat fusion operators become qualified (or trained)?

Some pipe manufacturers and authorized distributors of pipe, fittings and fusion equipment conduct training and operator qualification programs year round, both on-site and at their facilities. Details of a suggested training program are outlined in a PPI publication TN42, entitled, “Recommended Minimum Training Guidelines for PE Pipe Butt Fusion Training Operators for Municipal and Industrial Projects.” The PPI or pipe manufacturer’s recommended fusion joining procedures must be followed to assure a quality joint is produced.

Q. 40 Where do I get the equipment to fuse HDPE pipes?

A list of the of fusion equipment manufacturers can be obtained by contacting PPI The HDPE pipe distributor or pipe manufacturer may also be able to supply information in answer to this question..

Q.41 Can HPDE service tubing be joined with mechanical couplings?

Yes, mechanical couplings are commonly used on HDPE sizes 2” and below and come in a variety of installation methods such as stab type or interference fit. To maintain homogenous, leak free, and corrosion resistant HDPE service tubing systems, couplings molded from HDPE resins are preferred versus metallic (brass) couplings. Mechanical couplings molded from HDPE can offer significant excavation and labor cost savings and in general, require very little training and tooling to install. These service tubing fittings provide joints with the same integrity and life expectancy as fusion; however, some mechanical joints require the use of restraint devices, while other mechanical coupling products include stiffeners to prevent pullout of the final joint. Additional detail on the form and function of these products is available in the PPI Handbook 2nd ed., Chapters 9 and 15. Also, refer to PPI Technical Note TN22, PPI Guidelines for Qualification Testing of Mechanical Couplings for PE Pipes in Pressurized Water or Sewer Service.

Q. 42 Are gaskets required between the faces of HDPE flange adapters?

Generally it is not recommended or necessary that a gasket be used when making connections that involve two mating HDPE flanges for water pressure applications operating at 80 psi or less. However, special tightening of the bolting system is required and that may include re-tightening of the bolts in 4-hours to 24-hours after the initial torque. PPI publishes a technical note, TN 38 that deals with this subject in considerable detail and with other options for flanged connections made between HDPE and other pipe materials. It is strongly recommended that the design engineer/contractor refer to this document when faced with issues of design or assembly of any flanged connection involving HDPE pipe.

Q. 43 How is HDPE pipe connected and joined to PVC pipe?

Methods of joining HDPE pipe to PVC pipe vary with the size and style of PVC. Common methods include slip-joint anchor fittings, gasketed joint adapters, and flange connections. HDPE to PVC transition fittings are also available from certain fittings manufacturers; also, refer to PPI TN-36, General Guidelines for Connecting HDPE Potable Water Pressure Pipes to DI and PVC Piping Systems, for additional information.

Q. 44 How can HDPE pipe be connected to other pipe products such as ductile iron pipe or valves?

For pressure applications, HDPE transition fittings, HDPE mechanical-joint adapters, gasket-joint adaptors, HDPE flanges, and standard metal couplings with internal stiffeners are recommended. The most common method is to use an HDPE MJ (mechanical joint) adapter to connect the HDPE pipe end in a DI MJ bell using the bolt and gland kit supplied by the HDPE MJ manufacturer. DIPS sized HDPE pipe may be inserted directly into an MJ bell with a restraint ring and insert stiffener for the HDPE pipe. When joining HDPE pipe to a DI pipeline either the DI joints must be restrained or the transition connection must be anchored. More details of these mechanical joining systems can be found in Chapter 9 of PPI’s Handbook* of Polyethylene Pipe, 2nd ed. and PPI TN-36, General Guidelines for Connecting HDPE Potable Water Pressure Pipes to DI and PVC Piping Systems. Information on these systems may also be obtained from the pipe manufacturer.

Q. 45 Can butterfly valves be used with flanged HDPE pipe?

Yes. In some cases, depending on the butterfly valve dimensions, butterfly valve flange adapters, or standard flange adapters with tapered ID spacers are required in order for the valve to open & close freely. Consult with your flange adaptor or mechanical-joint adaptor supplier to insure dimensional compliance.

Q. 46 What is the recommended practice for joining HDPE pipe to mechanical joint valves and fittings?

An HDPE mechanical joint (MJ) adapter is fused to the HDPE pipe. The HDPE MJ adaptor is inserted into the metal MJ bell, with the standard gasket in place. The bolts through the gland are evenly tightened in a star pattern to complete the MJ connection.

Q. 47 What HDPE fittings are available for HDPE pipe?

Fittings are available in sizes from ½” to 65”. Molded elbows, tees and concentric reducers are standard up to 12”. Fabricated fittings that include elbows, equal tees, reducing tees, laterals, crosses, concentric reducers, and eccentric reducers are usually stocked up to 24”. Fabricated fittings up to 65” that include elbows, equal tees, reducing tees, laterals, crosses, concentric reducers, and eccentric reducers are available by custom fabrication. Flanges, mechanical-joint adapters, outlet branch saddles, pull heads, gasket joint adapters, MIPT, FIPT and Weld End connections are available in most sizes.

Q. 48 Are there HDPE valves available?

Yes, there are several manufacturers offering HDPE valves; at present, 16” is the largest size available for water applications.

Q. 49 Are stiffeners recommended for Mechanical-Joint (MJ) Adapters?

Yes, several manufacturers recommend stiffeners for all diameters; other manufacturers offer MJ adapters with stiffeners for diameters 12” and larger. For diameters above 12”, seasonal thermal contraction and creep under radial gasket pressure can decrease the nose diameter of the MJ adapter. But while the gasket thickness is the same for 4” to 24” pipe diameters, the reduction in the nose diameter of the adapter caused by a drop in temperature becomes larger with increase in diameters. As a result, there is a greater loss of compression (and sealing capacity) of the rubber gasket in the larger sizes. Hence, stiffeners are recommended in larger diameters above 12”. More information on this subject as well as results of various tests is available in PPI’s technical note TN22, PPI Guidelines for Qualification Testing of Mechanical Couplings for PE Pipes in Pressurized Water or Sewer Service, at www.plasticpipe.org. Consult with individual HDPE MJ adapter manufacturers for engineering information.

Q. 50 Will the existing municipal warehouse inventory of ductile iron fittings go to waste if I switch to an all HDPE piping system?

No. With the use of HDPE mechanical joint adapters, polyethylene pipe and ductile iron fittings are completely compatible. However, due to the flexibility and tighter bending radius that can be achieved with HDPE pipe, fewer fittings may be required.

Q. 51 How are service connections tapped onto HDPE pipe mains?

HDPE pipe can be cold or hot (under pressure) tapped using piping products presently available. Saddle fusion tapping tees, electrofusion tapping tees, electrofusion corp saddles, and branch-saddles are readily available. There are several bolt-on mechanical connections qualified for use with HDPE pipelines as well. With this variety of fittings, tapping is a straightforward procedure. More information on this topic is available in Chapter 9 of PPI’s Handbook of Polyethylene Pipe, 2nd ed.

Q. 52 Can a bolt-on tapping saddle/sleeve be used with HDPE pipe?

Generally speaking, many saddle manufacturers have saddles/sleeves specifically made for use with HDPE pipe and they are typically the same as those used with PVC pipe and sometimes the same as those used with Ductile Iron pipe. Service saddles often include double straps or extra wide straps and Belleville (spring) washers for use with HDPE pipe so that the tension on the strap remains constant once the nuts are properly torqued. As for tapping sleeves, some manufacturers such as JCM indicate that as long as it is a full sleeve in accordance with AWWA C110/111, it can be used on HDPE pipe.

Q. 53 Can HDPE pipe be direct threaded using the same tapping tools commonly used to tap PVC or ductile iron pipe?

No. Tapped threads are not recommended for use on HDPE piping products. The industry standards for service taps to HDPE mains recommend the use of saddle fusion tapping tees, electrofusion tapping tees, branch-saddles, and certain metal mechanical clamps.

Q. 54 Does HDPE pipe split in the same manner that can occur when PVC pipe is improperly tapped?

No. Due to the ductile nature of HDPE and the design of fittings used for tapping, no splitting will occur when properly “hot” tapping HDPE pipe.

Q. 55 Can HDPE pipe be joined by solvent coupling joints?

No. At this time, there are no known adhesives or solvent cements that are suitable for pressure sealing or that have sufficient strength characteristics to join HDPE pipes. Heat fusion, which includes butt fusion, electrofusion, saddle fusion and mechanical joints are the only methods for joining HDPE pipe.

D. INSTALLATION

Q. 56 How deep can HDPE pipe be installed?

Refer to the answer under question 27.

Q. 57 Are backfill procedures different for HDPE pipe vs. PVC pipe?

No. HDPE and PVC pipelines are installed using the same standard backfill procedures. Both are plastic materials requiring the same considerations for proper embedment and backfill. However, the particulars of the application may influence this somewhat. For example, very high DR (thinner wall) pipes installed under shallow cover that is subject to live loads may require a higher level of compaction of the embedment material than is required for pipes having lower DR’s i.e. stiffer pipe. Therefore, it is advisable to always follow the installation/backfill procedures recommended by the HDPE pipe producer or refer to Chapter 7 on underground installation of PE pipe in PPI’s Handbook of Polyethylene Pipe, 2nd ed.

Q. 58 Does HDPE pipe require cathodic protection? Can it be installed in “hot” soils that attack metal pipe?

HDPE pipe does not undergo galvanic corrosion and therefore it may be safely installed in hot soils that would attack metal pipes and there is no need for cathodic protection.

Q. 59 Are thrust blocks required with buried pressurized HDPE pipe?

Refer to the answer under question 29.

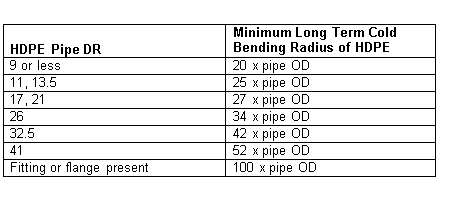

Q. 60 What is the allowable bending radius of HDPE pipe? How does it compare to PVC pipe?

HDPE pipes can safely be bent to a tighter radius than PVC; for the same size pipe, the HDPE pipe radius is about 1/10th the radius of PVC pipe. HDPE can be cold bent to the dimensions shown below for a long term application based on the pipe DR. Also, HDPE pipes may be bent to a tighter radius for a short term application, such as during installation.

Q. 61 How are HDPE pipelines located?

A tracer wire should be buried above the HDPE pipe at the time of installation to facilitate future location. If no metal wire was installed above the plastic pipe, ground-penetrating radar or acoustical resonance may be used.

Q. 62 What are the recommended procedures to pressure test a HDPE pipeline?

HDPE pipe should be pressure tested in accordance with PPI recommendations, (NOTE: other bell and spigot pipes are tested differently than HDPE – i.e. allowable leakage rates of bell and spigot versus expansion of PE ) For detailed information on this subject, refer to Chapter 2 of PPI’s Handbook of Polyethylene Pipe, 2nd ed. and to ASTM F2164, Standard Practice for Field Leak Testing of Polyethylene (PE) Pressure Piping Systems Using Hydrostatic Pressure

Q. 63 Compared to the host pipeline, when sliplining, what diameter HDPE pipe should be specified?

As a general or comfortable rule of thumb in sliplining applications involving sizes up to 24inches the outside diameter of the HDPE liner pipe should be about 90 percent of the inside diameter of the existing host pipe. For larger sizes the inside diameter of the host pipe should be about 2-inches greater than the outside diameter of the HDPE liner pipe, but this depends upon many factors including deflection, sag, bends, obstructions etc in the host pipe.. Therefore, it is advised that the design engineer refer to Chapter 11 of PPI’s Handbook of Polyethylene Pipe, 2nd ed. which covers “Pipeline Rehabilitation by Sliplining with PE Pipe.”

Q. 64 In sliplining and pipe bursting applications, is there another way to stop the tracking of ground water at the manhole, other than he use of chemical grout?

Yes. When HDPE pipe enters or exits a manhole it is best to use a link-seal or a water stop (also referred to as a puddle flange) with sealing grout. The link-seal or water stop will prevent water from seeping between the pipe and grout.

Q. 65 Must the entire annular space be grouted when sliplining with HDPE pipe for a water pressure application?

This depends on several factors such as a comparison of the applied internal operating pressure versus the external pressure from possible external loads, including earth loading, hydrostatic loading and superimposed loading. But while grouting of the termination points of internally pressurized systems is usual, grouting of the entire annular space is not often required. Irrespective, it is strongly recommended that the design engineer conduct an analysis of the project before deciding on the approach to this issue. For more details the reader is referred to Chapters 6 and 11 of PPI’s Handbook of Polyethylene Pipe, 2nd ed.

Q. 66 Are there any guidelines for the maximum length of HDPE pipe that can be pulled along the surface after fusing sections together?

The goal is, of course, to keep tensile stress in the pipe within allowable values for the pipe type and conditions. Maximum pulling length is a function of the tensile strength and weight of the polyethylene pipe, the temperature at which the pipe will be manipulated, the physical dimensions of the pipe, and the frictional drag along the length of the polyethylene pipe. Pipe rollers are available to reduce the friction between the pipe and the ground and allow longer lengths to be pulled. Equations 8 and 9 from Chapter 11, “Pipeline Rehabilitation by Sliplining with PE Pipe” of PPI’s Handbook of Polyethylene Pipe, are generally accepted for determination of the maximum feasible pulling length. One of the important factors in these calculations is the tensile strength of the particular polyethylene pipe product, which must be obtained from the manufacturer’s literature.

E. Maintenance & Repairs

Q. 67 When water freezes solid in an HDPE pipeline, will it damage the pipe? How is it most effectively thawed?

When water freezes solid in a HDPE pipe, it will not rupture it, but the pipe will expand with the ice. Obviously, the application of heat to the frozen section is really the only practical way to thaw it. But for safety considerations, and to avoid damage to the pipe, this must be done very carefully. One method is heat tracing. This involves wrapping the affected area with pressure sensitive metallic tape over which is wrapped temperature limited (120oF maximum) heat tracing tape. The metallic tape helps distribute heat evenly over the pipe surface. Heat blankets are also available, however torches or arc welders should not be used to thaw HDPE pipe. Consult the pipe manufacturer for more details on this or other thawing procedures recommended for use with HDPE pipe.

Q. 68 What percentage of external surface scratching or scarring is allowable on HDPE pressure pipe?

Scarring to a maximum depth of 10% of the pressure pipe wall thickness is generally tolerable. In fact, AWWA M55 states that “minor scratches or scuffing will not impair serviceability”. It also states that “pipe with gouges or cuts in excess of 10 percent of the product wall thickness should not normally be used”.

Q. 69 Is it possible to puncture HDPE pipe; how is that repaired?

Generally, only small diameter HDPE pipes can be severed by excavation equipment. And while it is possible to puncture pipe in diameters larger than 6” IPS with an excavator, it is usually a rare occurrence. More often excavator damage takes the form of kinking of the pipe. In larger diameters, the excavator cannot grip around the pipe or penetrate the thick wall. When external third-party damage does occur, there are several repair methods. For small punctures, electrofusion patches may be utilized. For larger damage, cut out the damaged section, then insert a spool piece and connect it on each end to the exiting pipe using mechanical fittings, flange adapters or electrofusion couplings. Depending on the extent of the damage full circle clamps may also be used as a temporary repair method. More detailed information on this subject can be found in Chapter 15 of PPI’s Handbook of Polyethylene Pipe, 2nd ed. Also, refer to PPI TN-35, General Guidelines Repairing Buried HDPE Potable Water Pressure Pipes.

Q. 70 How is HDPE pipe repaired without the use of heat-fusion?

As mentioned in the answer to the previous question mechanical fittings can be used. There are several types on the market that work very well. Experience has shown that most mechanical fittings work best when used in conjunction with a stainless steel stiffener and restrainers. For details consult with the pipe manufacturer or refer to Chapter 15 of PPI’s handbook. Also, refer to PPI TN-35, General Guidelines Repairing Buried HDPE Potable Water Pressure Pipes.

Q. 71 How do I repair HDPE pipe if the ditch is full of water?

If the ditch can be dewatered and the pipe dried off, fusion repair may be used. Otherwise a mechanical repair is recommended. Also, refer to PPI TN-35, General Guidelines Repairing Buried HDPE Potable Water Pressure Pipes.

Q. 72 What are some applications where an insert stiffener is required?

Insert stiffeners are normally used when inserting HDPE pipe into a PVC bell or DI MJ bell. The stiffener ensures compression of the gasket to the PE pipe. Stiffeners are also typically used in most mechanical fittings and in MJ adapters larger than 12” diameter. See also the answers to Questions 11 and 16 under the heading ’Joining’ in this document. Also, refer to PPI TN-35, General Guidelines Repairing Buried HDPE Potable Water Pressure Pipes.

Q. 74 Can I use a butterfly valve on HDPE pipe?

Refer to the answer under question 45.

Q. 75 Can I pig HDPE pipe?

Yes, but a soft pig should be used.

F. Costs

Q. 76 How will using HDPE pipe save money?

Refer to the answer under question 6.

Q. 77 Why does the price of HDPE pipe fluctuate?

Like all products there are many reasons for why their pricing may change, raw material costs, supply vs. demand, transportation costs, manufacturing costs (labor, energy) etc. For example, the raw material feedstock for HDPE pipe is HDPE resin which is a petroleum based engineered plastic. And so if petroleum prices change so also does the price of the resin used to make the pipe.

Q. 78 How do the prices of HDPE pipe compare with those of C-900 PVC pipe?

PVC and HDPE pipes are priced approximately the same when compared using the same basis; for example, using the same operating working pressure rating (WPR) and the same pipe outside diameters and the same minimum flow velocity of 5 fps, results in pipes with similar cost.

Q. 79 How does HDPE pipe compare in costs to ductile iron pipe?

The costs of ductile iron pipe and HDPE pipe are comparable on a material basis before taking into account the advantages of installing the longer lengths, lighter weight HDPE product. Additionally, the corrosion proof, leak proof and beneficial maintenance features of HDPE piping systems provide for a distinct and significant long-term cost advantage over ductile iron.

Q. 80 What would be the initial investment to purchase butt fusion equipment to fuse up to 12" ductile iron pipe size HDPE pipe?

There are now many different types of machines, sizes, models, and manufacturers to choose from in deciding to purchase a butt fusion machine. Therefore, the best answer to this question is to consult directly with the fusion equipment producer or with the HDPE pipe and fitting distributor for advice and quotation. Check the PPI web-site: www.plasticpipe.org for a listing of fusion machine manufacturers.

G. Case Histories

Q. 81 How long has HDPE pipe been used in water distribution and transmission applications?

HDPE has been used for these applications for over 50 years. After many years of field proven performance, it became a standardized material and product. The first American Water Works Association (AWWA) Standard for HDPE Pipe, C901 “Polyethylene (PE) Pressure Pipe and Tubing, ½ In. (13mm) through 3 In. (76mm) for Water service’, was adopted in 1978. The AWWA Standard for larger size HDPE pipe, C906, “Polyethylene (PE) Pressure Pipe and Fittings 4 In. (100mm) through 63 In. (1600mm) for Water Distribution and Transmission’ was adopted in 1990.

Q. 82 Where can I find a listing of historical installations of HDPE pipe successfully used in potable water distribution, transmission and river-crossing projects?

PPI, and its membership, maintains an extensive listing of case studies and cities which have installed HDPE water transmission, distribution, and service tubing. Refer to PPI and PPI member websites for a partial listing of case studies,http://plasticpipe.org/municipal_pipe/

H. Miscellaneous

Q. 83 In what lengths is HDPE pipe available?

HDPE pipe is available either in coils, reels or straight lengths (joints). Coils are normally available for 2” and smaller diameter pipe. The coil may contain 1,000 or more feet of pipe. 3”, 4”, and 6” diameter can also be made in coils or reels (steel or wood frames), but straight lengths are also common for these sizes. In diameters 3” and larger, straight lengths are typically 40’ or 50’. Longer lengths, i.e. 53’’ may also be an option for larger diameter pipe on large projects where it is advantageous to minimize the number of fusion joints, and thus, reduce construction costs.

Q. 84 What is an appropriate method for leak detection in HDPE pipe?

PE pipe is accepted as having the lowest leak-rate pipe system available (as evident by its use in natural gas distribution) As a “zero” leak-rate pipeline, there is no recommended specification for leak detection. Leak detection is a developing field with many technological improvements. One of the most promising techniques is the audio technique, which listens for the sound emitted as the fluid flows irregularly through an unplanned opening in the pipe.

Q. 85 Are there recommended DR’s for HDPE pipe for directional drilling applications?

HDPE pipe used in directional drilling must be designed to resist internal pressure, external loadings and pull back forces. Therefore, there is no standard or “cookbook” guideline for choosing an DR. However, there are data available to assist the designer in making an appropriate wall thickness selection. For detailed information on this subject, please refer to Chapter 12 of PPI’s Handbook of Polyethylene Pipe, 2nd ed. Similar information may also be available in the HDPE pipe manufacturer’s published literature.

Q. 86 Comparing HDPE pipe to other pipe materials, what is its level of acceptance in the water distribution market?

HDPE pipe is the fastest growing pipe product in the water market. The percentage rate of growth in usage for HDPE pipe has been in the double digits for the last decade. Based on other pipe association annual reports, this is well above the growth rate of other materials, and is above the growth rate of the water pipe market itself. HDPE pipe is widely accepted because of its corrosion resistance, zero-leak self-restrained fusion joint, durability, low maintenance and excellent long term performance history. In addition to the water market, the nuclear industry has adopted HDPE for its safety and non-safety related cooling water lines.

Q. 87 How much water is lost in a typical month from a ¼” diameter hole?

NASSCO reports that a pencil sized hole (1/4” diameter) in an 80 psi main results in approximately 15,000 gals/day or 450,000 gals/month of water loss.

Q. 88 Why is ASTM D1248 an obsolete standard for HDPE pipe materials?

Information regarding plastic pipe materials was removed from ASTM D1248 in 1989 and it was replaced by ASTM D3350 “Standard Specification for Polyethylene Plastics Pipe and Fittings Materials”. ASTM D 1248 was originally published in 1952 and is titled “Standard Specification for Polyethylene Plastics Extrusion Materials for Wire and Cable” In addition to wire and cable the early version of this standard also covered polyethylene materials for pipe. As the polyethylene piping industry grew the need for a stand alone standard specification for pipe became clear. The outcome was the development of ASTM D3350 which was first published in 1974 and continues in use today as the only ASTM standard specification that applies to the selection of materials for use in the manufacture of polyethylene pipe and fittings.

Q. 89 What happened to the ESCR (Environmental Stress Crack Resistance) test requirement?

It became obsolete because of the development of newer more robust high performance HDPE materials that proved virtually immune to failure in the ASTM D1693 ESCR test. This test has been replaced by ASTM F 1473 “Standard Test Method for Notch Tensile Test to Measure the Resistance to Slow Crack Growth of Polyethylene Pipe and Resins”. It is commonly referred to as the PENT test and it more closely models actual field conditions in terms of its ability to provide measurement of the pipe’s resistance to the initiation and propagation of slow crack growth (SCG) which can result from unanticipated localized stress intensifications. For more details of this test and its significance, the reader is referred to the ASTM standard itself or to Chapter 3 of PPI’s Handbook of Polyethylene Pipe, 2nd ed.

// ]]>